New Digital Twin Model to Revolutionise Strawberry Farming

A novel study published in the Open Access journal AgriEngineering demonstrates the development and validation of a new digital twin model of strawberry farms to train deep learning models. The digital twin enables considerable time and cost savings for researchers by integrating this sophisticated AI technology, providing highly accurate real-time information about the strawberry crops. Authors of the study, from the University of Florida, state the relevance and importance of the breakthrough:

“The study shows that a realistic digital twin can jump-start AI tool development for strawberry farms, enabling faster, more cost-effective robotics innovation,” said Dana Choi, a faculty member at the UF/IFAS Gulf Coast Research and Education Center.

In this article, we will discuss the basics of what a digital twin is, its importance in agricultural engineering and highlight the key findings of the study.

What is a digital twin?

A digital twin is a virtual space that reflects a real-life physical construct. This can be a physical person, item or system. Digital twin technology utilises a combination of AI and sensor technology. Information and data streams pass between the physical and digital systems in a feedback loop to provide real-time, accurate information about the structure.

Digital twins are highly useful and have been applied in a variety of industrial contexts. More recently, this has also included agriculture, where the role of the technology has been monumental. This includes its role in optimising irrigation systems, analysing the status and health of the crops and providing detailed information to aid in the development of agricultural innovations, such as robotic systems for industrial use.

Why are digital twins useful for farming?

Detection of fruit and size evaluation is critical for farmers. For this, deep learning algorithms are usually used, which require training from data sets that include real-life images of the crops at specific points in the harvest.

The authors of the study discuss how it is difficult to obtain a sufficient amount of data to train these algorithms, due to time and resource constraints, as well as narrow harvest windows.

Here, the authors demonstrate how using a digital twin and photorealistic simulation of a commercial strawberry farm can address the time and resource constraints associated with training AI models in agriculture.

Photorealistic simulation means that synthetic images are recreated from information obtained from the strawberry farms. This information can then be used to train deep learning AI models, even during non-harvest seasons.

Replicating strawberry farms

The authors first set out to replicate real-life commercial strawberry farms as closely as possible into a digital twin. They did this by allowing robots to take pictures of each and every part of the strawberry field to collect highly detailed images of each plant and portion of the farm.

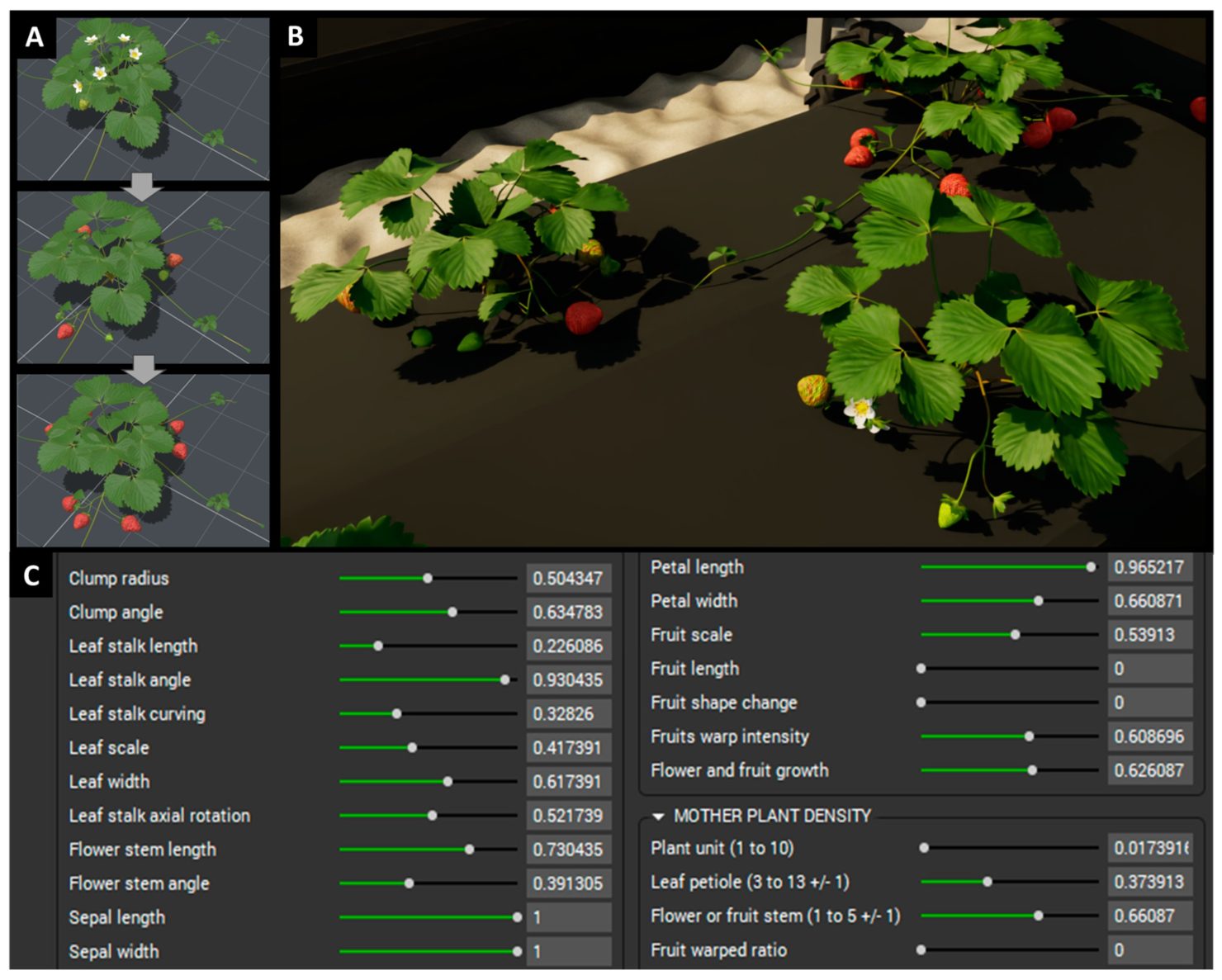

Developing a digital twin of a strawberry farm. 3D synthetic images developed from real-life images.

Developing a digital twin of a strawberry farm. 3D synthetic images developed from real-life images.

Side-by-side comparison of images taken from the strawberry farm with its digital twin.

Side-by-side comparison of images taken from the strawberry farm with its digital twin.

Following this, they were able to replicate 3D strawberry plant models, taking into account detailed measurements and characteristics of the plants, from the leaf stalk angle to the petal width of the plants, simulating a virtual version of the field.

This computer-generated field was a highly accurate replica of the physical field, possessing small discrepancies that were also present in the physical farms. The authenticity was confirmed by comparing information obtained from sensors in the strawberry farm with information obtained from simulated sensors in the digital twin farm.

Digital twins as the future of agriculture

There are no previous studies that completely use synthetic data to train AI models for fruit detection and size. This study shows a 92% accuracy in detecting fruit entirely from the synthetic simulated data.

Choi, one of the lead authors of the study, comments on how this can be an enormous development in the field of digital agricultural engineering.

“Because the computer-simulated field never goes out of season, new berry-spotting tools can be prototyped even in the summer, speeding innovation,” Choi said. “The findings also mean lower development costs. Companies can test robotic pickers or smart sprayer designs in the digital twin, first, ironing out bugs before real-life trials. That ultimately lowers the price of new technology.”

Essentially, using a digital twin cuts time and costs. Without a digital twin, scientists would have to wait for each harvest season to gather sufficient data to train AI models for further use. With this technology, scientists are able to test and train AI models all year round without time constraints, enabling faster and more efficient development of robotics as well as supporting future operator training.

Scientists would also be able to troubleshoot new machinery in a virtual environment before testing it in real life, potentially saving substantial costs, energy and time. Hence, digital twins present as an immensely sustainable option for the future of farming and agricultural engineering.

To read more about exciting new developments within the field of agricultural engineering, access the journal AgriEngineering, where all articles are free to read immediately. Alternatively, you can access MDPI’s full journal list.